3D printer filament is the thermoplastic material used by most FDM/FFF 3D printers. The printer feeds this filament into a heated nozzle, melts it, and deposits it layer-by-layer to form a printed object.

Most filament comes on spools and is typically sold in 1.75 mm (most common) or 2.85 mm diameter. The material you choose affects print strength, surface finish, durability, temperature resistance, and how easy it is to print.

Common Types of 3D Printer Filament (And What They’re For)

1) PLA (Polylactic Acid)

Best for: beginners, prototypes, display models, low-stress parts

Why people use it: prints easily, low warping, good detail, wide color range

Trade-offs: lower heat resistance; can soften in hot cars or near heat sources

2) PETG (Polyethylene Terephthalate Glycol)

Best for: functional parts, brackets, containers, parts needing toughness

Why people use it: tougher than PLA and generally less warp-prone than ABS

Trade-offs: can string; needs tuning for cleaner results

3) ABS (Acrylonitrile Butadiene Styrene)

Best for: durable parts, enclosures, mechanical components

Why people use it: better heat resistance than PLA, good toughness

Trade-offs: prone to warping; prints best with an enclosure and stable temperatures

4) TPU / TPE (Flexible Filaments)

Best for: phone cases, gaskets, grips, vibration dampers, flexible parts

Why people use it: rubber-like flexibility with good impact resistance

Trade-offs: slower printing; more sensitive to moisture

5) Nylon (Polyamide)

Best for: gears, bushings, functional parts that take repeated stress

Why people use it: strong, wear-resistant, excellent layer bonding (when dry)

Trade-offs: highly moisture-absorbing; needs careful storage

6) ASA

Best for: outdoor parts, UV exposure, weather resistance

Why people use it: similar to ABS but better UV resistance

Trade-offs: still benefits from an enclosure; can warp if conditions fluctuate

7) Polycarbonate (PC)

Best for: high-strength, higher-heat parts

Why people use it: strong and temperature resistant

Trade-offs: requires higher temps; not ideal for entry-level printers

8) Filled Filaments (Carbon Fiber, Wood, Glow, Metal-fill)

Best for: stiffness (CF), aesthetics (wood/metal), special effects

Why people use it: unique finishes or improved rigidity

Trade-offs: many are abrasive—often require a hardened nozzle; print settings vary

Typical Filament Uses by Project Type

- Prototypes & visual models: PLA

- Functional brackets & daily-use parts: PETG

- Heat-tolerant parts (moderate): ABS / ASA

- Outdoor prints: ASA (preferred)

- Flexible parts: TPU

- Mechanical wear parts: Nylon (when properly dried)

- High-performance engineering parts: PC, Nylon blends, CF-reinforced materials

How to Choose the Right Filament (Simple Checklist)

Choose by performance needs

- Need easy printing and clean detail? → PLA

- Need toughness without a full enclosure? → PETG

- Need higher heat resistance? → ABS or ASA

- Need flexibility? → TPU

- Need strong wear-resistant parts? → Nylon (must be kept dry)

Choose by your printer setup

- No enclosure / open frame: PLA, PETG, TPU (usually easier)

- Enclosure available: ABS, ASA, Nylon, PC become more realistic

- Standard brass nozzle only: avoid abrasive filled filaments long-term

- Hardened nozzle: better for carbon fiber / glow / metal-fill filaments

Choose by where the part will live

- Hot environment (car, near heat): avoid PLA

- Outdoor sunlight: consider ASA for better UV resistance

- Humid environment: storage matters as much as material choice

Filament Storage: Recommended Humidity (RH) + Practical Tips

Filament absorbs moisture from the air. When it gets “wet,” prints can show stringing, popping/bubbling, rough surfaces, and weaker layers—and this hits TPU and Nylon the hardest.

Recommended humidity to store filament:

-

PLA / PETG / ABS / ASA: 20–30% RH

-

TPU / Nylon / PC / PVA (more moisture-sensitive): 10–20% RH

-

If you want one all-round setting: ~20% RH is a strong default for mixed spools.

Simple storage tips that work:

-

Keep spools in a sealed box/bag with desiccant when not printing.

-

Don’t leave filament exposed above 40–50% RH for long periods.

-

If print quality suddenly drops, dry the spool and store it correctly again.

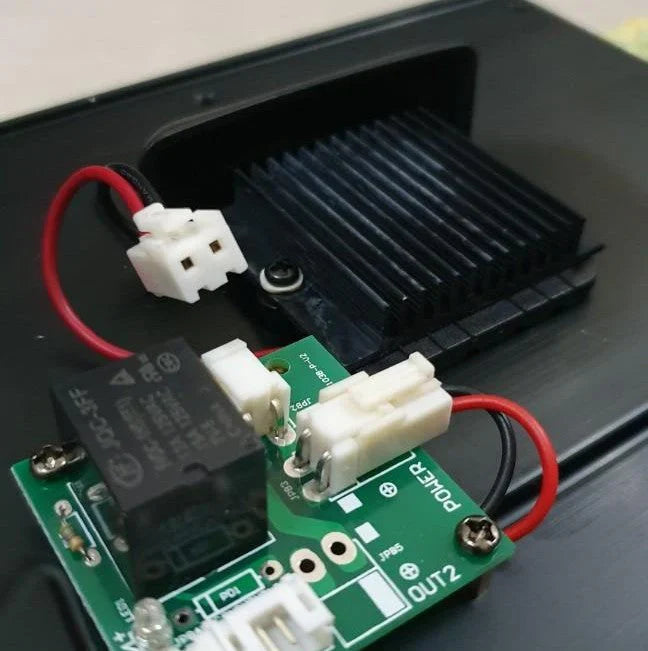

If you want a set-and-forget solution for consistent humidity control, a dry cabinet is one of the cleanest ways to protect filament long-term—especially in humid climates. You can reference a dry cabinet option here.