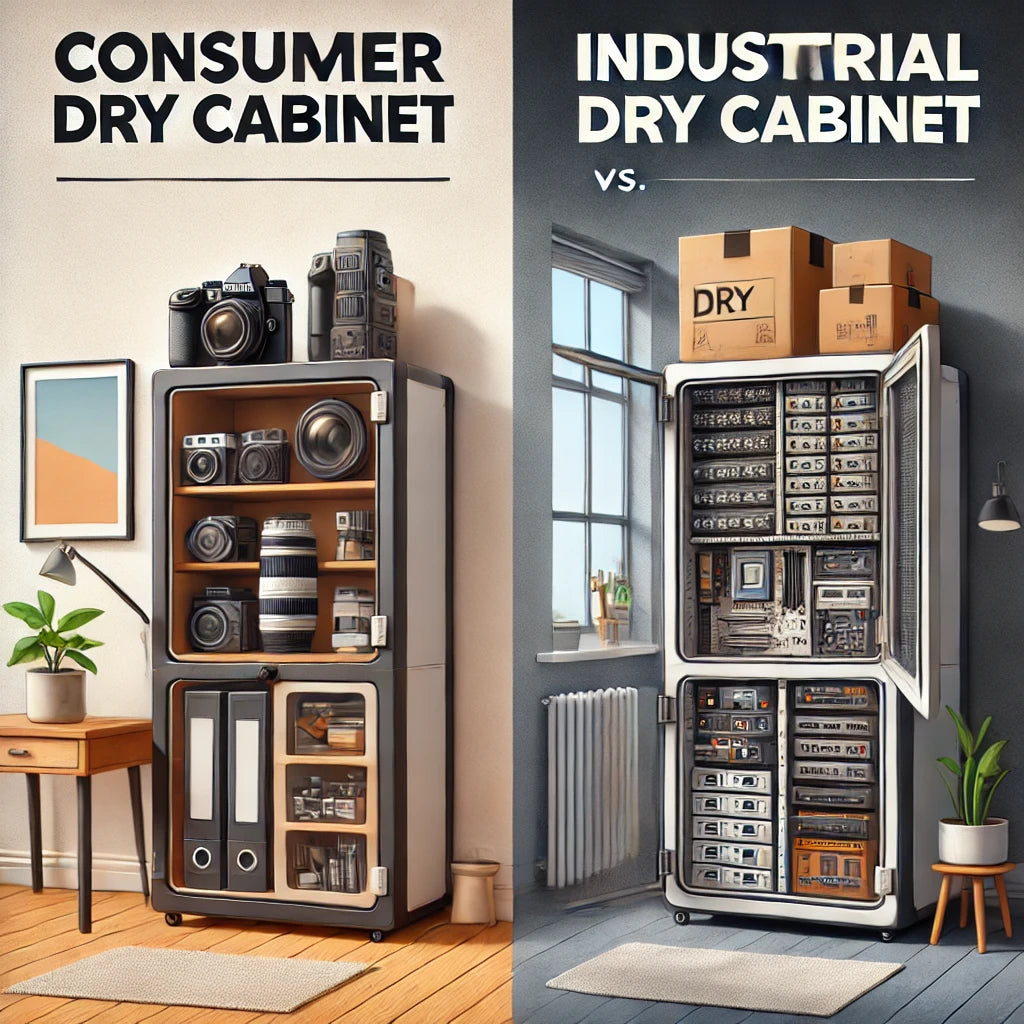

In the semiconductor manufacturing industry, maintaining optimal environmental conditions is essential for ensuring the quality and reliability of electronic components. One of the most critical aspects of this process is the control of humidity levels to prevent moisture-related defects. This is where dry cabinets come into play.

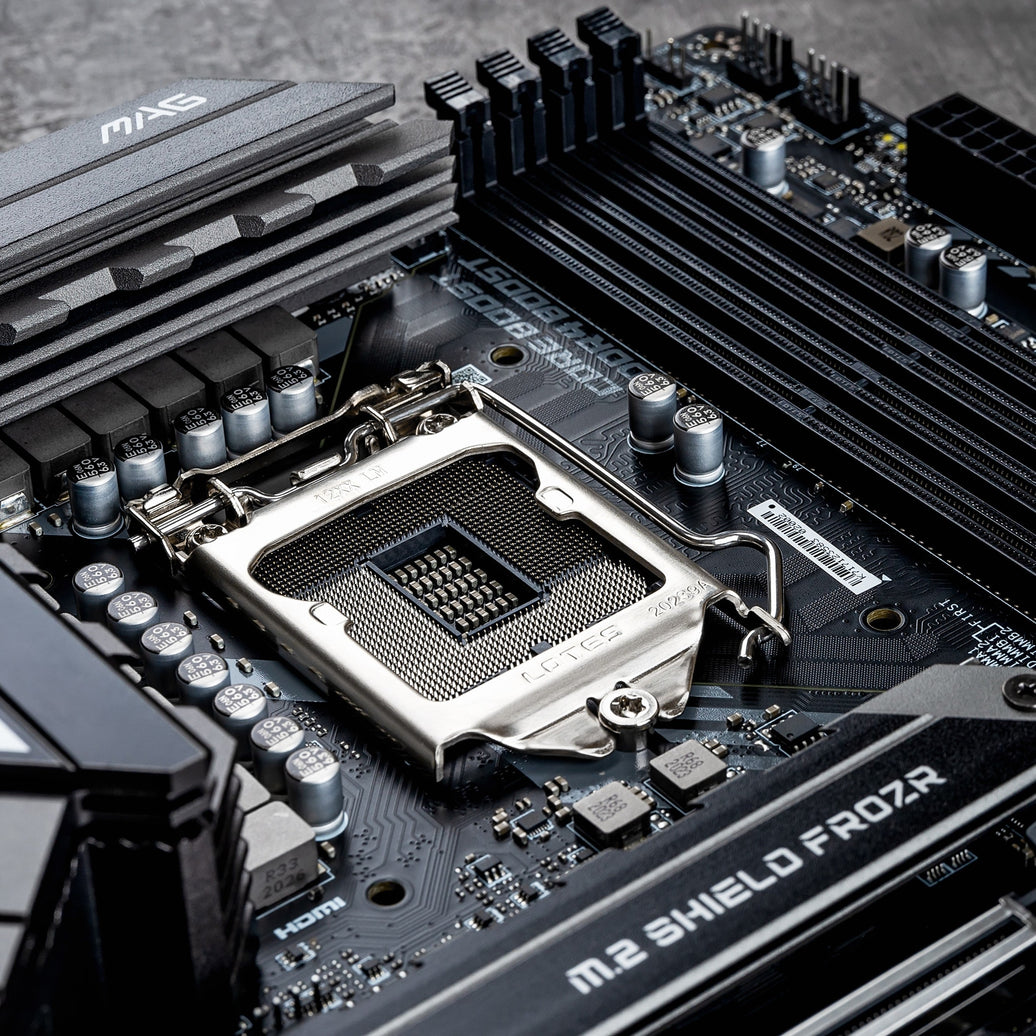

Dry cabinets are specially designed storage units that provide a low-humidity environment, essential for preserving the integrity of moisture-sensitive devices (MSDs). In semiconductor manufacturing, components such as integrated circuits (ICs), surface-mount devices (SMDs), and printed circuit boards (PCBs) are highly susceptible to moisture absorption. When exposed to high humidity, these components can suffer from a range of issues, including:

- Popcorning: This occurs during the soldering process when absorbed moisture rapidly expands, causing the component to crack or delaminate.

- Corrosion: Moisture can lead to the oxidation of metal contacts, resulting in poor electrical connectivity and potential failure.

- Electrochemical Migration: Excess moisture can cause the movement of metal ions across a dielectric surface, leading to short circuits and component failure.

Dry cabinets maintain humidity levels as low as 1-5% RH (relative humidity), significantly reducing the risk of these defects. By storing components in such controlled environments, manufacturers can ensure that their products meet stringent quality standards and have a longer shelf life.

In addition to preventing defects, dry cabinets offer several other benefits in semiconductor manufacturing:

- Enhanced Yield Rates: By reducing moisture-related failures, dry cabinets help increase the yield rates of production lines.

- Cost Savings: Preventing defects and failures translates to cost savings by reducing the need for rework and scrap.

- Compliance with Industry Standards: Many industry standards, such as IPC/JEDEC J-STD-033, mandate the use of dry cabinets for moisture-sensitive devices. Compliance ensures that manufacturers meet regulatory requirements.

Overall, the use of dry cabinets in semiconductor manufacturing is a critical practice that helps maintain product integrity, reduce waste, and ensure the reliability of electronic components. By preventing moisture-related defects, dry cabinets play a vital role in the efficiency and success of the semiconductor industry.