Understanding Dry Cabinets in Industrial Settings

Dry cabinets are essential tools in various industrial sectors, particularly in electronics manufacturing and pharmaceuticals. These specialized cabinets help in controlling the humidity levels within their environment, which is crucial for maintaining the integrity and functionality of stored items. Here’s a simplified look at how dry cabinets are used in these industries and how they differ from their consumer counterparts.

1. Electronics Manufacturing

- Purpose: In electronics manufacturing, dry cabinets are used to store sensitive components like printed circuit boards (PCBs) and integrated circuits. These components can be damaged by moisture, leading to corrosion or device failure.

- Humidity Control: Industrial dry cabinets can maintain humidity levels below 40%. This level of control is crucial to prevent moisture absorption that can lead to soldering defects and other manufacturing issues.

2. Pharmaceuticals

- Purpose: Pharmaceutical companies use dry cabinets to store drugs and biological materials that are sensitive to moisture. Proper storage ensures that these materials maintain their efficacy and shelf life.

-

Humidity Control: Like in electronics, controlling the humidity is vital. Excessive moisture can lead to degradation of active ingredients and compromise the safety and effectiveness of pharmaceutical products.

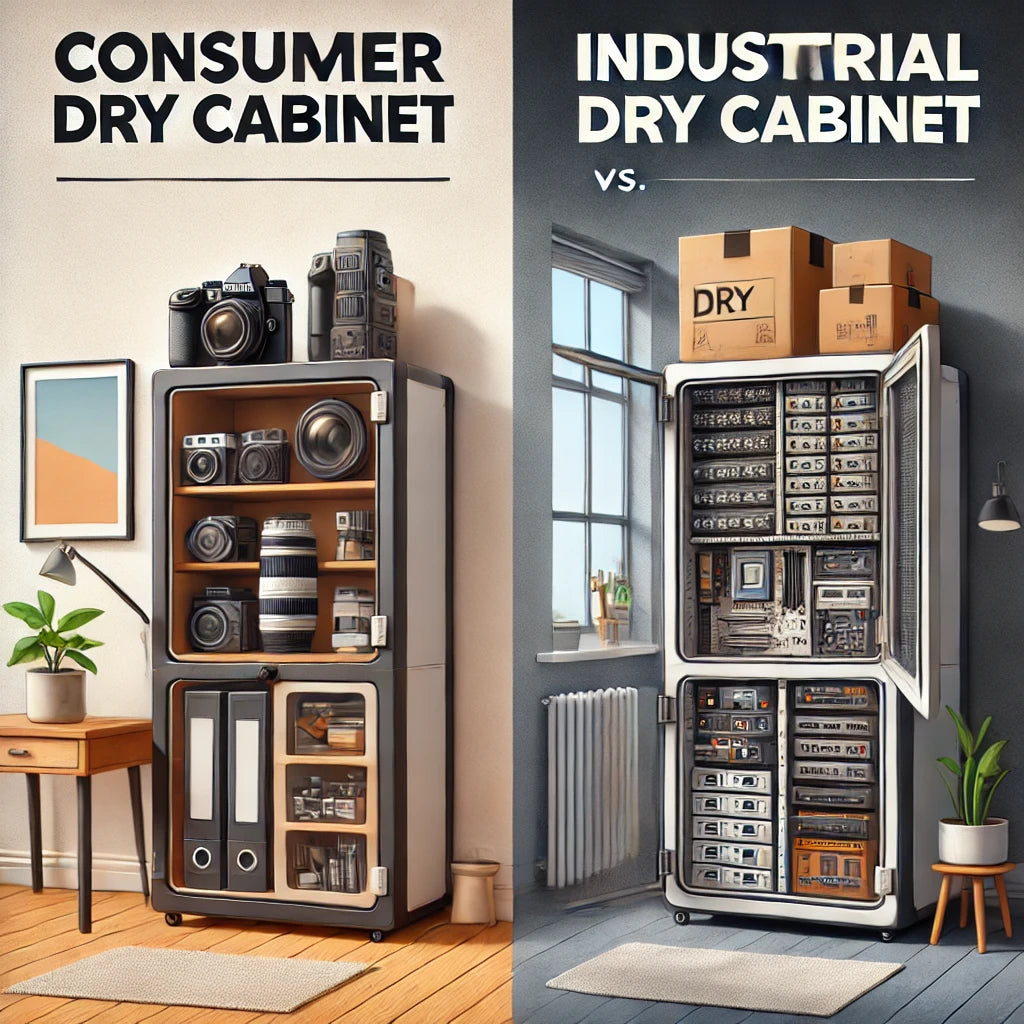

Differences Between Industrial and Consumer Dry Cabinets

-

Humidity Levels: The most significant difference lies in the humidity control range. Industrial dry cabinets are designed to control humidity levels significantly lower than 40%, which is essential for sensitive industrial materials. Consumer dry cabinets typically control humidity within a range of 40% to 60%, suitable for general household items like cameras and musical instruments but not adequate for industrial needs.

-

Capacity and Build Quality: Industrial dry cabinets are often larger and built with higher durability to withstand the rigors of industrial environments. They may also feature more advanced technologies for monitoring and adjusting humidity levels.

-

Precision and Reliability: Industrial units offer more precise control over humidity and are built to operate continuously under varying conditions. Consumer units may not offer the same level of precision or reliability, which is suitable for less critical storage.

Why Choose Industrial Dry Cabinets?

For industries like electronics manufacturing and pharmaceuticals, the choice of an industrial dry cabinet is driven by the need for ultra-low humidity environments. This control is crucial not just for the quality of the products but also for meeting strict regulatory standards and reducing waste due to spoilage or manufacturing errors.

Using the right type of dry cabinet can significantly enhance product reliability and longevity, making it a critical investment for high-stakes industries. By understanding the specific needs of your industry and how these tools can meet them, businesses can make informed decisions that boost efficiency and product quality.